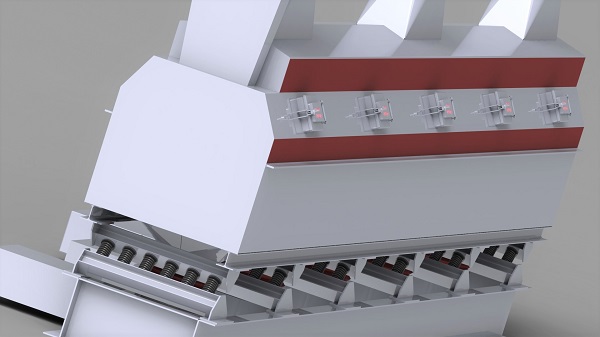

Fluidized Bed Dryers

Fluidized bed dryers are widely used in various industries such as food, chemical, pharmaceutical, etc. for the efficient drying of granular materials. Its structure usually consists of a chamber, air distributor, heating element, and cyclone separator. The drying process works by forcing a hot air flow through the granular material, causing the material to become suspended or "fluidized". This ensures uniform heat transfer and rapid drying.

Small-Capacity Fluidized Bed Dryer

- Evaporation Capacity: 100 kg/hour

- Fuel Consumption: 100,000 kcal/hour

- Dimensions (W x L x H): 2 m x 2 m x 3 m

- Features:

- Energy Efficiency: Utilizes a high-efficiency heat exchanger

- Control System: Precise temperature and humidity control with a digital control panel

Medium-Capacity Fluidized Bed Dryer

- Evaporation Capacity: 300 kg/hour

- Fuel Consumption: 250,000 kcal/hour

- Features:

- Automatic Loading and Unloading System: Ensures continuous material flow with automated systems

- Rapid Drying Technology: High airflow for quick and uniform drying

Large-Capacity Fluidized Bed Dryer

- Evaporation Capacity: 600 kg/hour

- Fuel Consumption: 500,000 kcal/hour

- Features:

- Dual Rotary Fan System: Improved air circulation for more efficient drying

- Low Carbon Emissions: Eco-friendly energy usage with a reduced carbon footprint

Industrial Fluidized Bed Dryer

- Evaporation Capacity: 1,000 kg/hour

- Fuel Consumption: 800,000 kcal/hour

- Features:

- Multi-Phase Heat Recovery System: Reduced energy consumption through heat recovery

- High Durability: Stainless steel construction for long life and robust performance

These models are customizable to meet diverse industrial needs and cater to varying drying capacity requirements. Additionally, each model offers key advantages in fuel consumption, dimensions, and energy efficiency, enabling businesses to optimize their operational costs effectively.

One of the main advantages of fluidized bed dryers is their ability to process heat-sensitive materials without spoiling them. Efficient heat transfer enables rapid drying, reducing processing times and increasing productivity. Furthermore, the flexibility of the system means that it can be used for a variety of applications, such as sterilizing powders, grains and even spices. However, there are some disadvantages, such as uneven drying under certain conditions and design complexity for large-scale operations. Special designs, such as horizontal fluidized bed dryers, can help overcome these challenges by providing better airflow control and more efficient drying.

In the food industry, fluidized bed dryers are particularly effective at drying delicate products such as fruit, vegetables and herbs, as they preserve their texture and nutritional value. The fluidization process ensures even drying, which is critical to maintaining the quality of these delicate materials. However, fluidized bed dryers are not suitable for all materials, as fine powders or very sticky materials may not fluidize properly, which can lead to problems with drying efficiency. Despite these limitations, fluid bed dryers are essential to industries that need efficient and continuous drying processes, and advances in technology are continually improving their design and performance.

English (United Kingdom)

English (United Kingdom)  French (fr-FR)

French (fr-FR)  Turkish (tr-TR)

Turkish (tr-TR)