Production Steps

- Reception and intermediate storage of the sawdust

- Drying and possibly intermediate storage again

- Screening for foreign materials such as stones and metal

- Hammer-milling and possibly intermediate storage

- Pressing of the pellets

- Cooling of the pellets

- Screening of fines

- Storage

- Bagging

- Loading out

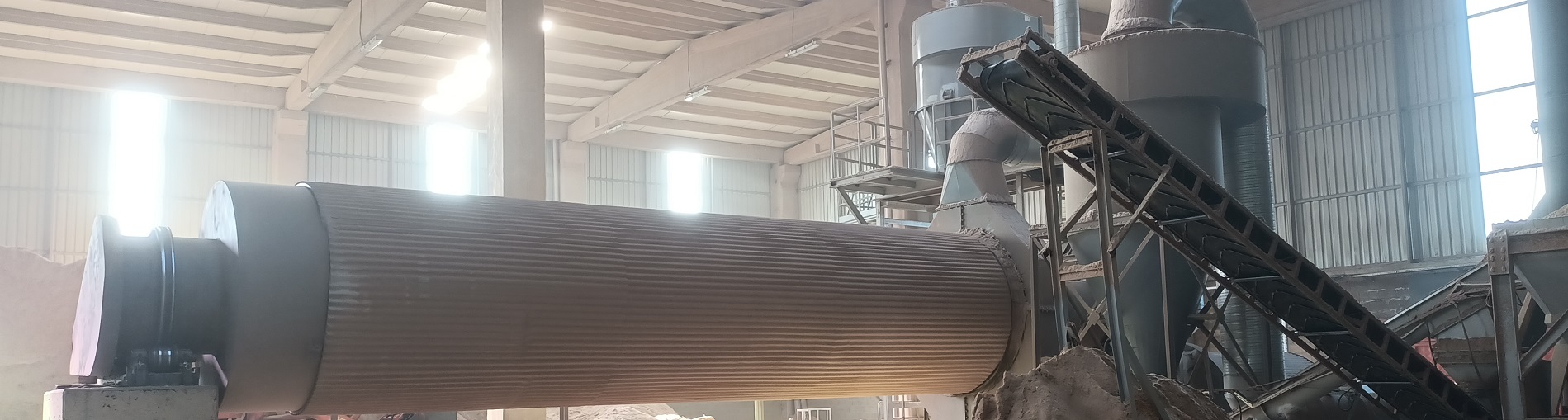

Various types of dryers are used to dry wood sawdust, depending on the moisture and capacity of the sawdust.

Jet Drying System: It is mostly used for drying sawdust at low capacities of 1 ton / hour and below and with a moisture content below 30%. Exceeding the capacity and exceeding the limit temperatures are not recommended in this drying system.

Single Pass Drying System: It must be of high length to meet the required replacement time (stay in the drum) for drying the sawdust. For this reason, it is generally not recommended to use this drying type in the sawdust drying system.

Double Pass Drying System: This is the drying system we recommend for capacities of 1 ton and above, up to 5 tons / hour. It is a drying system with high energy efficiency and low production costs.

Three Pass Drying System: It is a drying system that we recommend for drying sawdust of 5 tons / hour and above. Although it is one of the most efficient drying systems for drying because the three drums are nested inside each other, the size of the drying system directly affects the product price.

Wood pellets are typically manufactured using clean conifer sawdust and planer shavings, which must be debarked beforehand at the sawmill. While hardwood sawdust can be mixed with softwood, producing hardwood pellets without binders proves more challenging.

Ideally, sawdust and shavings with a moisture content below 15% are used to eliminate the need for a drying stage. However, if the material contains more moisture, it must be dried before pellet pressing. Occasionally, small quantities of wood chips are introduced during the drying phase to increase feedstock volume, and these chips are later ground in a hammer mill.

Alternatively, if pellets are made directly from roundwood, additional steps like debarking and chipping are required, which can substantially raise production costs. Since wood chips are much larger than sawdust, achieving the necessary fine texture for pellet pressing often demands multiple passes through the hammer mill.

Additionally, chips take longer to dry compared to sawdust, necessitating a larger drying capacity when roundwood serves as the primary raw material for the pelleting process.

Machines Used in the Production Line

English (United Kingdom)

English (United Kingdom)  French (fr-FR)

French (fr-FR)  Turkish (tr-TR)

Turkish (tr-TR)