Modern Powder Detergent Production Line: 7-Stage Process That Increases Productivity and Quality

In today's fast and competitive production world, efficient and quality production processes have become more important than anything else. Powder detergent production is a complex process that requires high precision and technological infrastructure. Our company allows you to manage this process in the most efficient and high-quality way with its modern powder detergent production line. Here are each stage of this production line:

- Stockpiling of Raw Materials

Every successful production process starts with the right raw material. The transportation and storage of raw materials used for powder detergent production is a very critical step. Our company ensures that raw materials are transported properly without damaging their structure. These materials, which are stored in two different sections as liquid and solid, are stored safely in suitable tanks. - Dosing of Raw Materials

Raw materials are transported to be mixed in appropriate quantities according to a specific recipe. Our company controls this dosing process completely automatically and precisely with PLC (Programmable Logic Control) units. In this way, you can ensure standard quality and correct component ratios in every production batch. - Mixing the Slurry and Aging

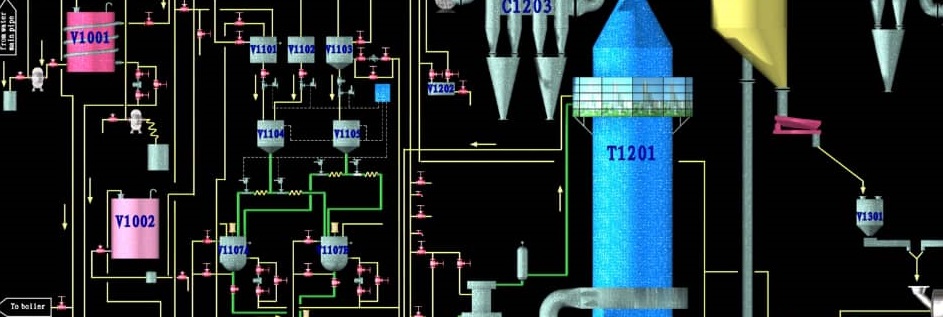

After the dosing process, the raw materials are transferred to mixing tanks. Here, the material is mixed homogeneously and subjected to a waiting process called "aging". This process ensures that the effective formulation of the detergent is obtained and extends the shelf life of the product. - Spray Drying Process

The mixed slurry is sent to the spray tower with high-pressure pumps. In the tower, the liquid mixture is atomized at high temperatures and dried quickly. Our company's advanced technology spray drying system guarantees homogeneous drying of the product and the obtaining of smooth particles. - Filtration Process

After the drying process, the harmful substances remaining from the resulting dust and steam mixture are cleaned from the system. Our company uses modern filtration systems to clean the dust and dirt in the air in the most efficient way after the drying process, thus protecting both product quality and environmental health. - Post Blending

Special ingredients that cannot undergo the spray drying process, such as enzymes, fragrances and color additives, are added to the original mixture at this stage. The post blending process creates the final formulation of the powder detergent and allows you to create personalized products. - Packaging

The final stage is the packaging of the final product. The produced powder detergent is directed to automatic packaging machines and packaged fresh and of high quality. The packaging process is carried out in accordance with the customer demands of the product under high hygienic conditions.

English (United Kingdom)

English (United Kingdom)  French (fr-FR)

French (fr-FR)  Turkish (tr-TR)

Turkish (tr-TR)